Electra, a startup backed by Bill Gates and Amazon, has opened its first steel production plant in the United States. This pilot plant, located in Colorado, utilizes renewable energy to produce clean metallic iron from high-impurity ores. The process aims to create "green" steel, which could significantly reduce the environmental impact of steel production.

By integrating renewable energy resources, Electra achieves emissions-free iron production at a much lower temperature than traditional coal-fired furnaces. Their clean iron has a purity of over 99%, making it valuable for electric arc furnace (EAF) steelmakers. This innovative approach represents a significant step toward a cleaner and more sustainable steel industry.

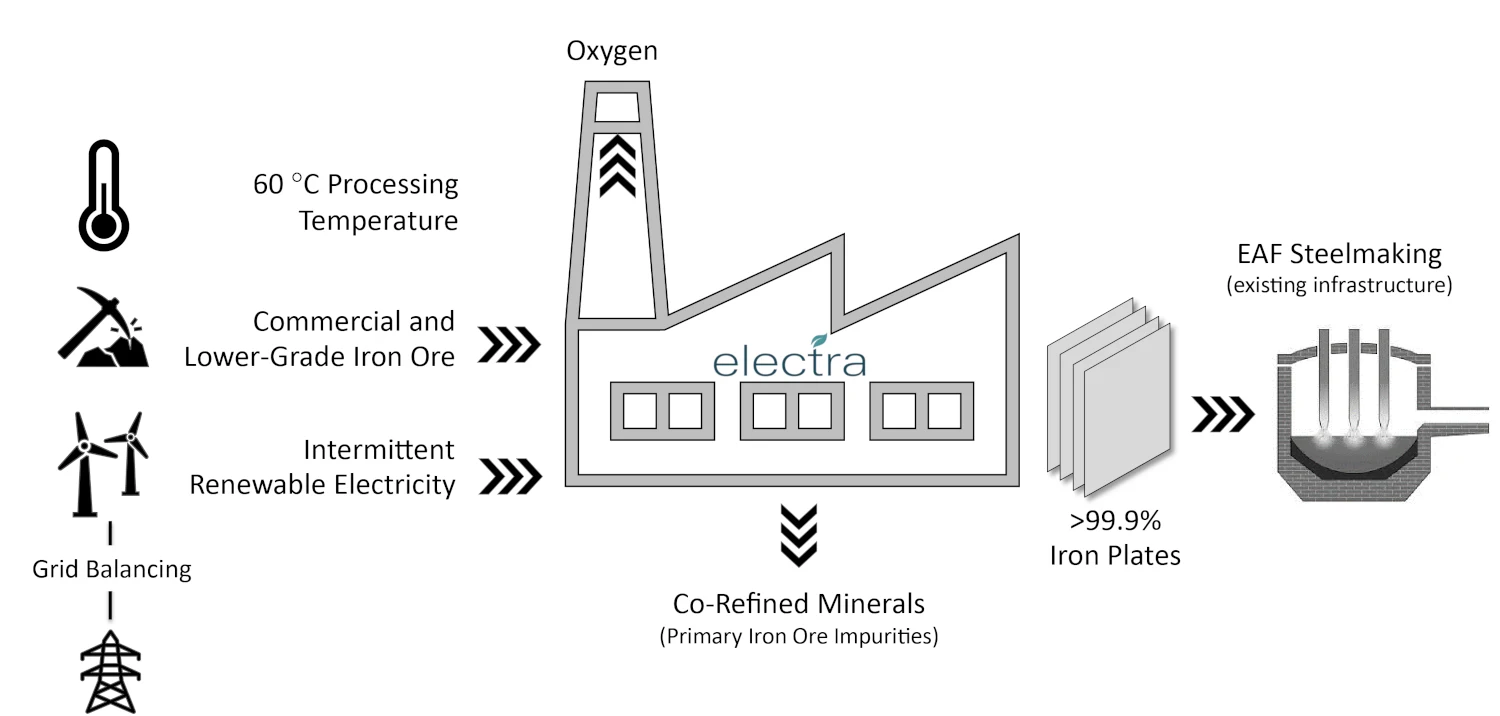

Electra has developed a groundbreaking process for green steel production. Electra's method operates at a mere 60 degrees Celsius (around the temperature of coffee), which is significantly lower than traditional steelmaking processes that rely on coal-fired furnaces. Electra uses a proven industrial-scale electrochemical and hydrometallurgical process. Here are the key steps:

- Dissolving Iron Oxide: First, they dissolve iron oxide ore in an aqueous acid solution.

- Precipitating Metals: This step allows them to selectively refine the main impurities in iron ore, such as alumina and silica, as co-products.

- Direct Reduction: Electra directly reduces iron oxide into iron without the need for a blast furnace or coal burning.

|

This is a significant improvement compared to traditional steelmaking methods that rely on melting high-grade ores with coal, emitting 10% of global carbon dioxide emissions.

Electra's pilot plant represents a significant step toward a cleaner, more sustainable, and circular steel industry. Partnerships across the value chain support their goal of producing millions of tonnes of clean iron by the end of the decade.

In summary, Electra's process aims to bend the trajectory of climate change by creating green steel through innovative technology and sustainable practices.

In October 2022, Electra raised $85 million in Series B round of funding from notable group of backers including Bill Gates-founded Breakthrough Energy Ventures, Amazon, BHP Ventures, Temasek, S2G Ventures, Capricorn Investment Group, Lowercarbon Capital, Valor Equity Partners, and Baruch Future Ventures.

Several other companies are also actively working on green steel production, aiming to reduce the environmental impact of steelmaking.

Swedish startup, H2 Green Steel, is building a large-scale plant in Sweden that will produce steel using hydrogen made from renewable energy instead of coal. By the end of next year, they plant to begin making steel for customers like Ikea and Mercedes-Benz. Their goal is to produce 5 million tons of green steel annually.

Boston Metal uses electrolysis to create steel from iron ore. By leveraging this innovative process, they aim to reduce emissions associated with traditional steel production.

Arcelor Mittal and China Baowu Group have also announced commitments to net-zero steelmaking, championing solutions for a more sustainable industry.

IndianWeb2.com is an independent digital media platform for business, entrepreneurship, science, technology, startups, gadgets and climate change news & reviews.

IndianWeb2.com is an independent digital media platform for business, entrepreneurship, science, technology, startups, gadgets and climate change news & reviews.