- Polymateria and Toppan Specialty Films have released packaging which fully biodegrades leaving no microplastic and toxins behind.

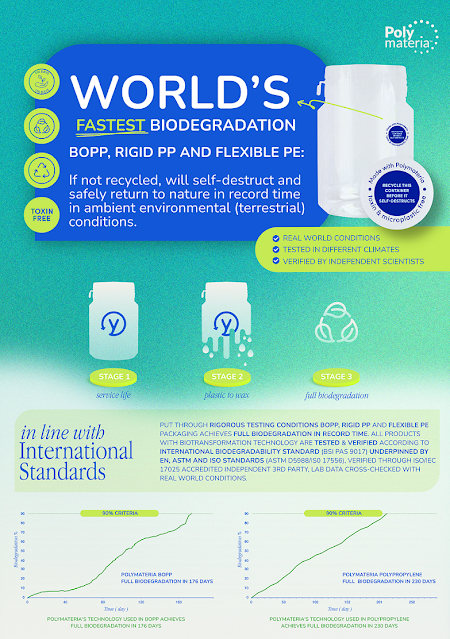

- Data released today shows that biotransformed packaging can return to nature in record time – 176 days.

- The revolutionary technology does not affect the mechanical or aesthetic qualities and allows plastic to be recycled for a pre-determined amount of time via a time-set feature.

- Biotransformation technology will help push boundaries in the plastics industry, propelling the switch to more sustainable materials across the value chain in India.

Polymateria also worked with one of the world’s largest confectionery manufacturers to create rigid plastic packaging armed with biotransformation technology, which was measured to fully biodegrade in 230 days, breaking a previous record of 310 days. These twin breakthroughs mean that common packaging from candy wrappers to cigarette packaging could be made biodegradable - with important impacts on the 11 million tons of plastic waste which reach the ocean every year [1].

The first prototypes of biotransformed plastics developed through the partnership between Polymateria and Toppan were verified by the fully accredited AIMPLAS Technological Institute of Plastic laboratory in Spain, which tested the plastics under the ISO 17556 standard for biodegradability.

|

Mr Niall Dunne, CEO of Polymateria said, “I’m delighted to be announcing our record-speed biodegradation here in India given the leadership role the country is playing on tackling plastic pollution. In a market the size of India, multiple solutions will be needed and our technology provides an additional route by making plastic fully biodegradable in the ambient environment. Working with sustainability champions like Toppan gives me great hope that by coming together the industry will rise to the challenge."

Mr Manohar Kumar, CEO of Toppan Speciality Films said, “We are delighted to see the record-speed biodegradation achieved by combining our plastic packaging with Polymateria’s technology. We are already seeing huge interest in our sustainable biodegradable packaging in India and look forward to working with some of the country’s most well-known brands as it gets widely rolled out.”

Products using Polymateria’s technology can be recycled, but if they escape into nature, they will biotransform into a bioavailable wax. The wax then attracts microorganisms like bacteria and fungi, which safely digest it and return it to nature without harm.

Biotransformation technology will be part of the solution to the global problem of plastic pollution, and Toppan is leading the way in adopting innovative technologies which can be brought to scale rapidly. This technology has the potential to significantly boost the sustainability of the packaging industry, in conjunction with other measures including improved waste management systems, consumer education and further innovative ideas from both government and the private sector. Time is running out to tackle plastic pollution, with some projections suggesting there will be more plastic than fish in the ocean by 2050 [2]. Governments and businesses across many sectors need to work together to create a cleaner future.

About Polymateria’s Biotransformation Technology

Plastic with Polymateria’s technology is made for recycling, however, if it escapes into the natural environment and is exposed to natural elements such as sun, air, moisture and heat, it will biotransform into a bioavailable wax. The wax attracts microorganisms like bacteria and fungi which safely digest it and return it to nature without harm.

Biotransformation technology is integrated into plastics at the point of manufacture, meaning there is no need for CAPEX investment and solution can be scaled immediately by plastic producers around the world. Furthermore, plastics with biotransformation technology look and feel exactly like conventional plastic for their entire service life, offering manufacturers, both a convenient and sustainable solution without compromising on quality.

About Polymateria

Polymateria aims to utilise scientific advancements to address the issue of plastic pollution. Established at Imperial College London, the company has become the first entity to demonstrate, through scientific evidence, that the most prevalent sources of unmanaged plastic waste can be returned to nature without generating microplastics, negatively impacting the ecosystem or disrupting recycling processes on a large scale. As a result of its efforts to promote circularity and combat plastic pollution, Polymateria was honoured as a World Economic Forum Tech Pioneer in 2021.

About Toppan

Toppan Specialty Films is a global leader in the development and production of specialty and value-added films (majority PP based) with strong focus on providing sustainable solutions of clearly differentiated quality used in flexible packaging of food, confectionery and fast moving consumer goods, as well as in industrial packaging. The company is known for its innovative, sustainable solutions that help customers meet their packaging needs while reducing their impact on the environment.

[2] The New Plastics Economy https://www3.weforum.org/docs/WEF_The_New_Plastics_Economy.pdf

Mr Manohar Kumar, CEO of Toppan Speciality Films said, “We are delighted to see the record-speed biodegradation achieved by combining our plastic packaging with Polymateria’s technology. We are already seeing huge interest in our sustainable biodegradable packaging in India and look forward to working with some of the country’s most well-known brands as it gets widely rolled out.”

Products using Polymateria’s technology can be recycled, but if they escape into nature, they will biotransform into a bioavailable wax. The wax then attracts microorganisms like bacteria and fungi, which safely digest it and return it to nature without harm.

Biotransformation technology will be part of the solution to the global problem of plastic pollution, and Toppan is leading the way in adopting innovative technologies which can be brought to scale rapidly. This technology has the potential to significantly boost the sustainability of the packaging industry, in conjunction with other measures including improved waste management systems, consumer education and further innovative ideas from both government and the private sector. Time is running out to tackle plastic pollution, with some projections suggesting there will be more plastic than fish in the ocean by 2050 [2]. Governments and businesses across many sectors need to work together to create a cleaner future.

About Polymateria’s Biotransformation Technology

Plastic with Polymateria’s technology is made for recycling, however, if it escapes into the natural environment and is exposed to natural elements such as sun, air, moisture and heat, it will biotransform into a bioavailable wax. The wax attracts microorganisms like bacteria and fungi which safely digest it and return it to nature without harm.

Biotransformation technology is integrated into plastics at the point of manufacture, meaning there is no need for CAPEX investment and solution can be scaled immediately by plastic producers around the world. Furthermore, plastics with biotransformation technology look and feel exactly like conventional plastic for their entire service life, offering manufacturers, both a convenient and sustainable solution without compromising on quality.

About Polymateria

|

Polymateria aims to utilise scientific advancements to address the issue of plastic pollution. Established at Imperial College London, the company has become the first entity to demonstrate, through scientific evidence, that the most prevalent sources of unmanaged plastic waste can be returned to nature without generating microplastics, negatively impacting the ecosystem or disrupting recycling processes on a large scale. As a result of its efforts to promote circularity and combat plastic pollution, Polymateria was honoured as a World Economic Forum Tech Pioneer in 2021.

Toppan Specialty Films is a global leader in the development and production of specialty and value-added films (majority PP based) with strong focus on providing sustainable solutions of clearly differentiated quality used in flexible packaging of food, confectionery and fast moving consumer goods, as well as in industrial packaging. The company is known for its innovative, sustainable solutions that help customers meet their packaging needs while reducing their impact on the environment.

———

[1] Breaking The Plastic Wave: https://www.pewtrusts.org/-/media/assets/2020/07/breakingtheplasticwave_report.pdf[2] The New Plastics Economy https://www3.weforum.org/docs/WEF_The_New_Plastics_Economy.pdf

IndianWeb2.com is an independent digital media platform for business, entrepreneurship, science, technology, startups, gadgets and climate change news & reviews.

IndianWeb2.com is an independent digital media platform for business, entrepreneurship, science, technology, startups, gadgets and climate change news & reviews.